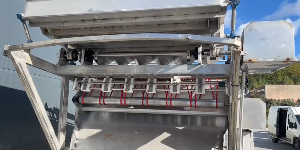

2012 Cabinplant Roller grader 12 rollers

Specifications

| Manufacturer | Cabinplant |

| Model | Roller grader 12 rollers |

| Year | 2012 |

| Rollers | 6 pcs, 3 m long |

Description

A 12 rollers Cabinplant roller grader initially intended for size grading Mackerel. The machine is in good conditions and has been in little usage.

· https://www.cabinplant.com/solutions/axial-roller-grader/

Technical overview

Type Designation 6, no. of grading lanes

6, no. of rollers – 2 each lane

3, length of rollers in meters

6, no. of size categories

Function For gentle and effective size grading of pelagic fish

Capacity 5 ton/hour

Rule of thumb 1/5 t/h of sardines per lane based on 12-20 fishes/kg

2.5 t/h of herring per lane based on 6 fishes / kg

3.0 t/h of mackerel per lane based on 3 fishers / kg

Operation Product is fed onto the vibration feeder that separates, rectifies and distributes it evenly to all grading lanes. The product slides down the gradually wider lanes, so the small items fall through first and the large ones further down the lane. Oversized product continues over the end of the rollers.

Construction The roller grader is built of stainless steel with maintenance-free closed bearings mounted inside the rollers in a sealed plastic housing. The rollers are driven by round belts that are easily changed.

The machine consists of four main elements: the vibratory infeed, the rollers, a frame with guide plates on the top of the rollers, plus support and chutes underneath the rollers.

The vibratory feeder is mounted at the high end of the rollers to lead the product down into each lane via guide plates. The feeder is complete with vibration motors with adjustable stroke length