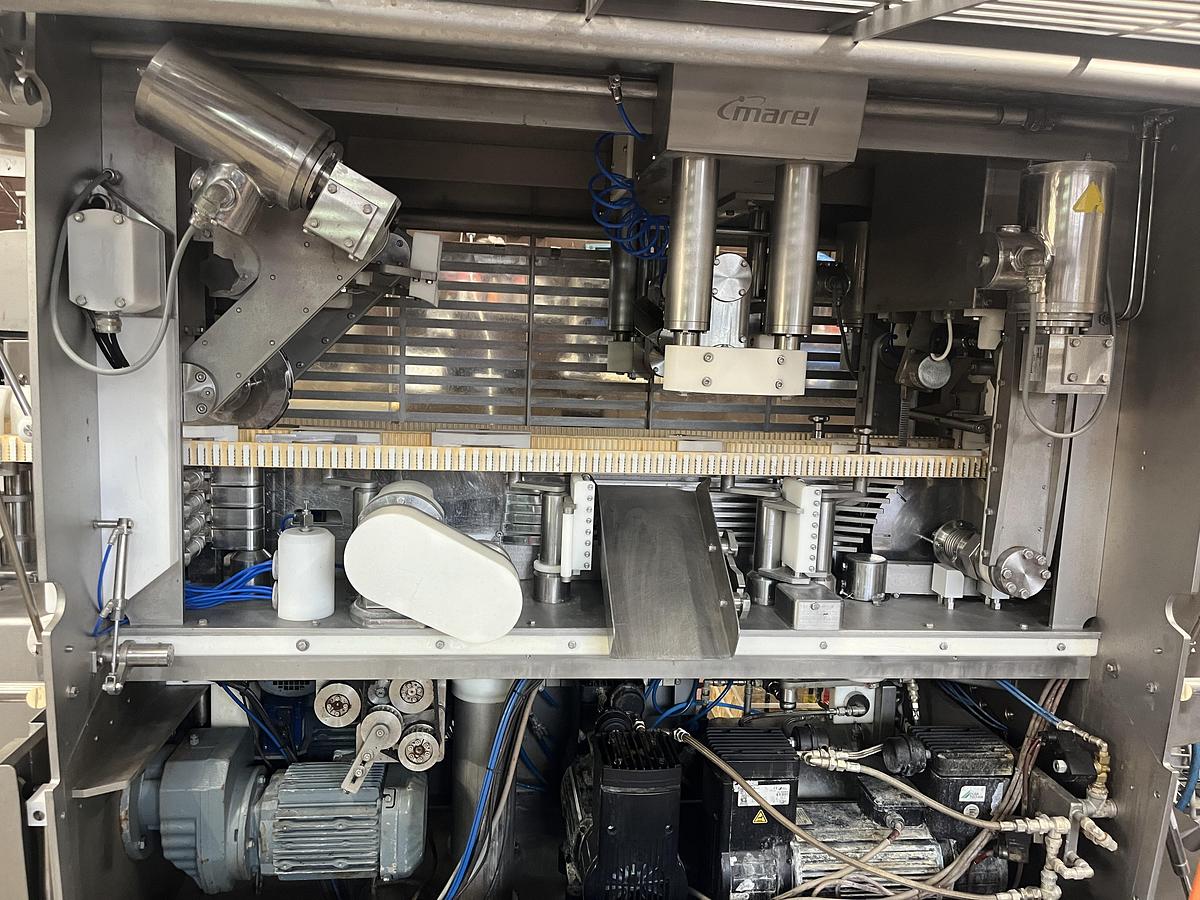

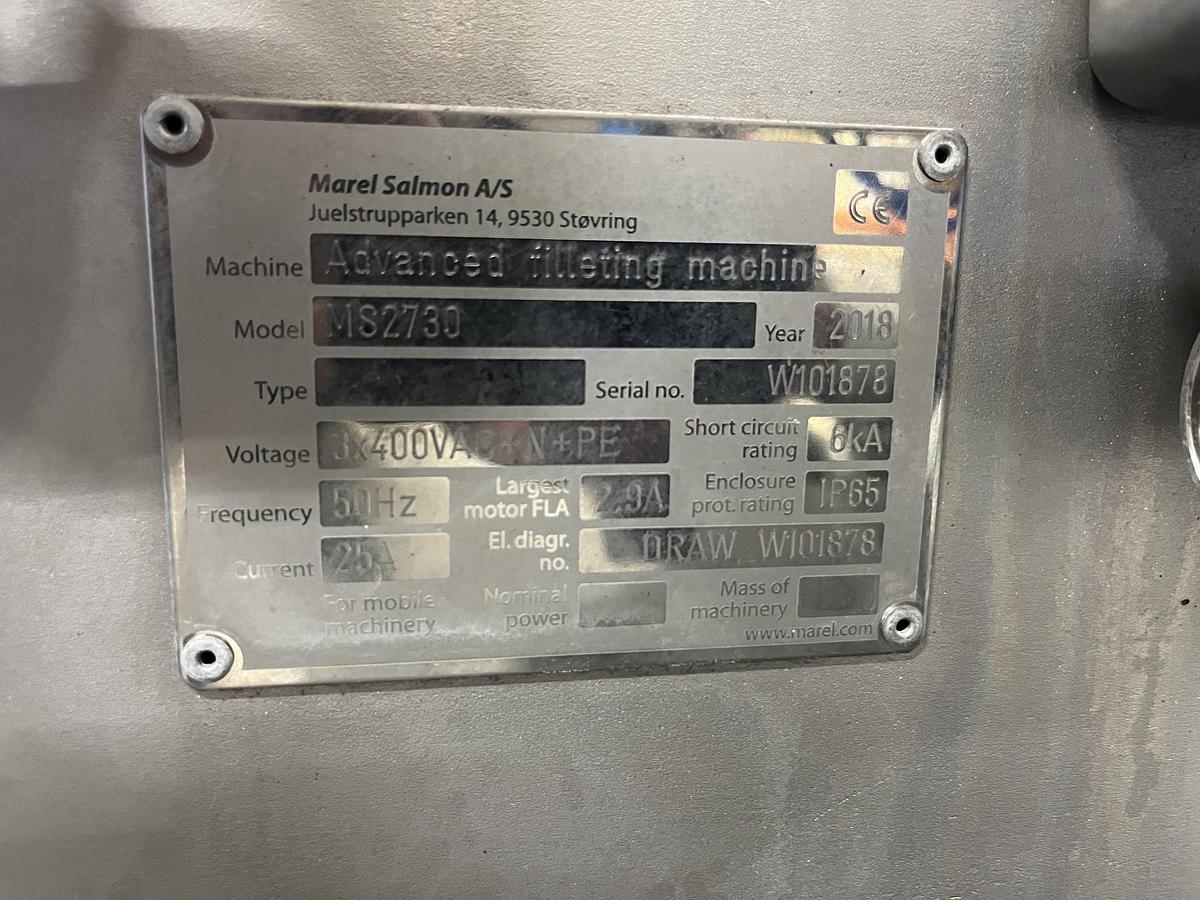

MAREL 2730 Salmon filleting machine

Specifications

| Manufacturer | MAREL |

| Model | 2730 |

| Year | 2018 |

| Stock Number | 00056 |

| Fish size | 1,5-8 kg |

| Capacity | Up to 25 fish/minute |

| Power consumption | 5.5 kW |

| Water consumption | 15 liters/min |

Description

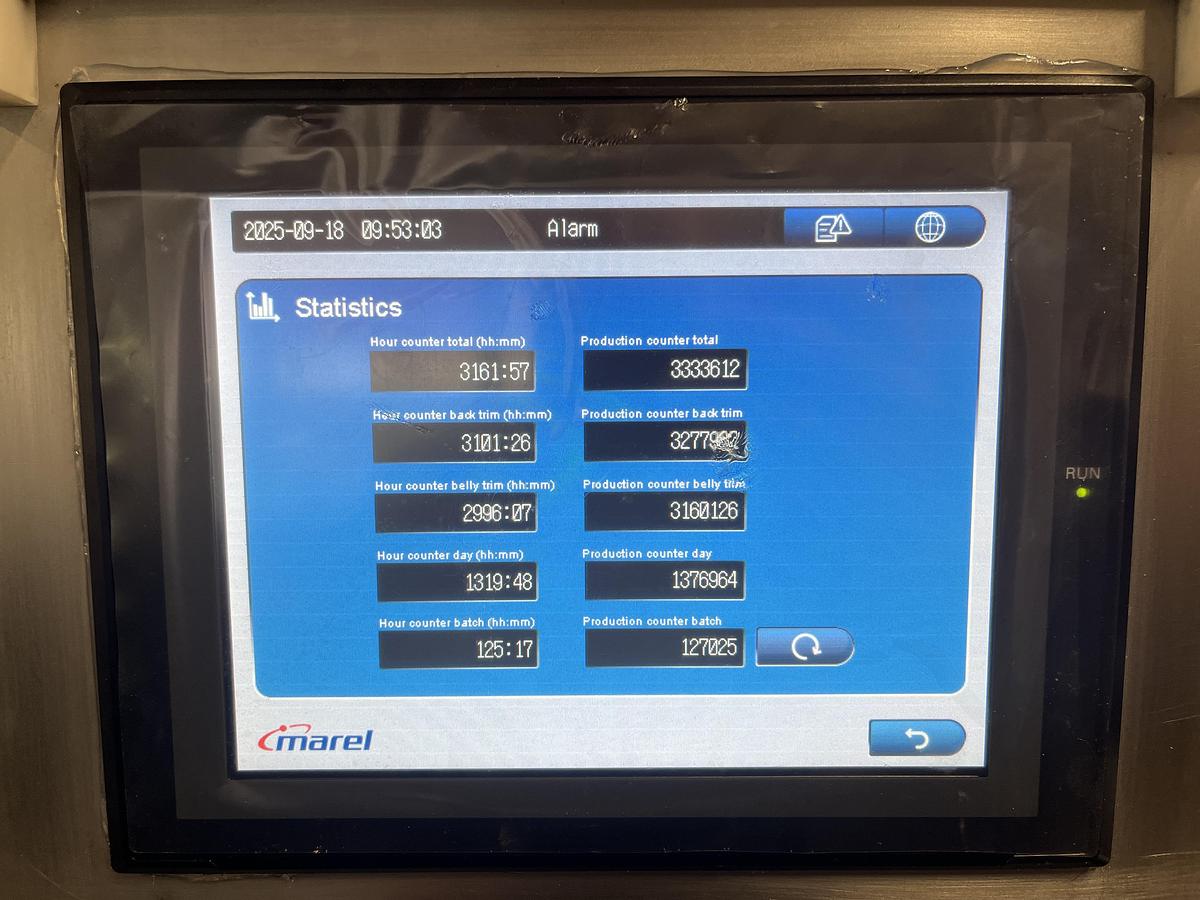

The Marel MS 2730 is an automated salmon filleting machine designed to maximize yield and throughput, capable of processing up to 25 fish per minute. It features automated size adjustments via a touch screen, includes advanced back and belly trimming, and is built for easy operation and hygiene. The machine accommodates salmon from 1.5 to 8 kg, with optional kits available for smaller fish, and is part of Marel's larger processing solutions.

Key Features and Capabilities

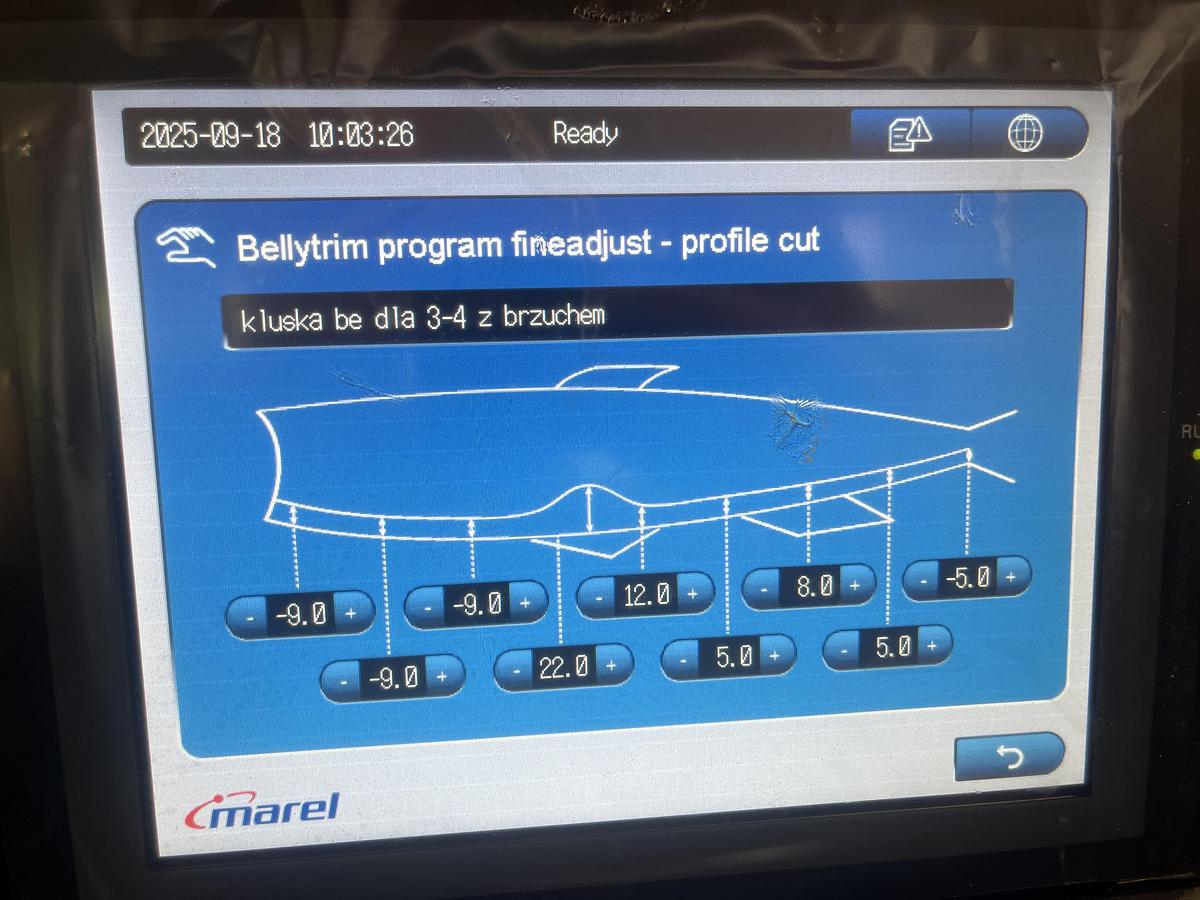

- Automated Processing: The MS 2730 automatically adjusts to different fish sizes and uses electronically controlled tools to maintain high quality and consistent results.

- High Throughput: It can fillet up to 25 salmon per minute, increasing production efficiency.

- Improved Yield: The design includes a set of circular knives that capture meat near the center bone, significantly increasing fillet yield.

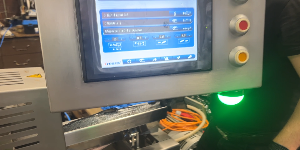

- User-Friendly Operation: A multilingual color touch screen provides easy and safe control over all operations, with pre-programmed settings for different fish sizes.

- Compact Design: The machine has a compact footprint, allowing for easier integration into existing processing lines.

Technical Specifications

- Fish Size: Standard 1.5 to 8 kg, with a kit available for fish as small as 500 g.

- Water Consumption: Approximately 15 liters per minute.

- Power Requirements: Operates on 3 x 400V and requires a 3.3 kW power supply.

Benefits for Processors

- Efficiency: Streamlines workflow with automated adjustments and high-speed processing.

- Quality & Yield: Produces high-quality fillets by including more meat and minimizing waste.

- Flexibility: Accommodates various fish sizes and is part of a larger, integrated system for comprehensive processing solutions.

- Cost-Effectiveness: Optimized water consumption reduces operating costs.

The fish is fed into the machine belly down, which makes the infeed much easier and faster. An additional set of circular knives cuts the fish from vent to tail. This cut raises yield, as the meat close to the center bone is included in the fillets. For the belly bone cut, 4 sets of finger pressures secure maximum control of the fish and enable optimum cutting of both pre-rigor and post-rigor fillets. The result is high-quality fillets with higher yield and output. The MS 2730 automatically adjusts to various fish sizes, so there is no need to adjust once the program has been switched on. The MS2730 can process up to 25 fish per minute, depending on the length of the fish. With the built-in system for measuring the fish´s profile and size, the electronically controlled cutting tools can automatically adjust the filleting program to the fish´s size and shape. The result is higher throughput, quality and yield depending on trim specifications. With the optional small fish kit installed, the MS 2730 is capable of filleting fish weighing from 500 g up to 4 kg.

Capacity:Up to 25 fish/minute

Fish size:1,5-8 kg

Power consumption:5.5 kW

Water consumption:15 liters/min

Electricity:3 x 400V + N + PE / 3 x 220V + PE

Air supply:230-240 l/min at 7-8 bar

Dimensions L x W x H: 3150 x 1035 x 1980 mm