In poultry processing, post-freeze product quality largely determines plant competitiveness. Modern consumers demand frozen meat that looks fresh, cooks evenly, and retains natural structure, flavor, and juiciness after thawing.

KAPP Skaginn IQF Tunnel Freezer

Traditional spiral or air tunnel systems frequently cause product dehydration, texture loss, and deformation. The KAPP Skaginn IQF tunnel freezer eliminates these via Individual Quick Freezing (IQF) technology, preserving product integrity while maintaining high process efficiency.

Surface Freezing Preserves Natural Structure

Engineered for precision and repeatability, the KAPP Skaginn tunnel freezer serves poultry, seafood, ready meals, and breaded products. Its two-stage process combines surface "crust" freezing and core freezing in one continuous cycle. Patented Teflon-coated aluminum belts rapidly form a thin ice layer in the first stage, locking in natural juices and preventing dehydration. This protects muscle fibers, keeping meat elastic and succulent. "Post-thaw products are firm, retain natural structure, and look like fresh meat." Poultry processors achieve premium yields without sacrificing line speed.

Flexible Configurations Match Any Production

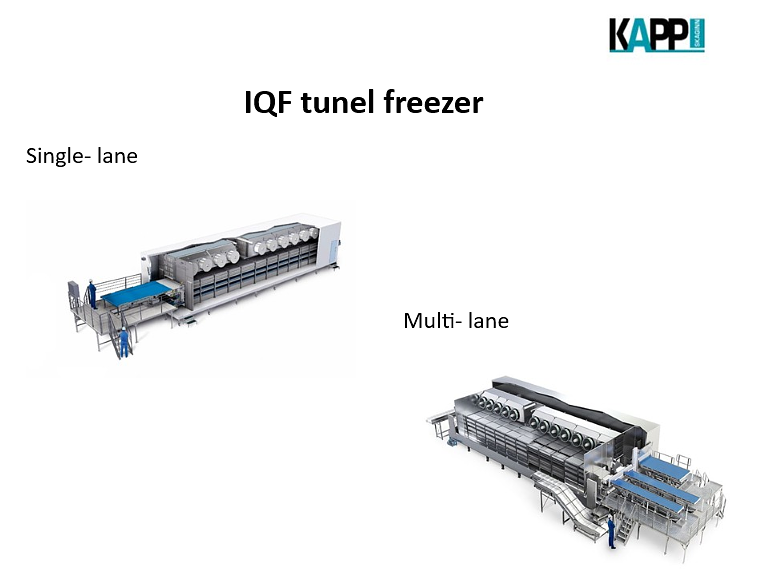

The KAPP Skaginn tunnel freezer comes in two setups for diverse process needs:

- Single-lane – ideal for uniform-sized products requiring consistent freezing time

- Multi-lane – independent control of multiple streams with varying parameters

Capacities range from 500 kg/h to 9000 kg/h, suiting medium and large processing plants. Both deliver precision, flexibility, and continuous operation stability.

Designed for Integration and Efficiency

Stainless steel construction with food-grade plastics and Teflon belts ensures durability, easy maintenance, and rapid cleaning. Runs continuously for a full week without washdown—daily evaporator defrosting maintains optimal cooling. Seamlessly integrates with existing cutting, sorting, or packaging lines.

Proven Industrial Performance

User data confirms KAPP Skaginn's efficiency gains:

- Reduced product weight loss – down to 0.2–1.3%

- Higher yields – less moisture loss and production waste

- Consistent quality – stable structure, volume, and color post-thaw

This combination of throughput, hygiene, and yield improvement sets a new IQF standard in poultry processing.

KAPP Skaginn Success in Brazil

Brazil's booming food sector drives demand for KAPP IQF tunnel freezers among top poultry and seafood producers.

BRF S.A. Partnership

Global giant BRF ordered a multi-lane IQF tunnel freezer for its Dourados poultry plant (after successful Toledo installations). Iceland-made with three independent belts, it delivers up to 6 t/h capacity and 40% faster surface freezing for premium quality and energy efficiency.

C. Vale Expansion

Leading pork, poultry, and tilapia processor C. Vale bought its first KAPP Skaginn in 2018, recently adding a dual-lane fish model and triple-lane poultry unit—each reaching 4 t/h. IQF technology ensures stable yields and repeatable quality across fish, poultry, and meat.

Bernico – Official KAPP Distributor

Poland & Baltic States