MAREL Proline

eller

Ring +48 505 131 190

Specifikationer

| Tillverkare | MAREL |

| Modell | Proline grader M3000 |

| År | 2009 |

| Lagernummer | 00058 |

| Application | Fish and chicken elements |

| Capacity | 100 pcs/min |

| Subsubcategory | Grader/Batcher |

| Power supply | 3 x 415 Volt + N / 50 Hz |

| Availibilty | Available |

| Dimensions | 10 m |

Beskrivning

16 station whole bird grader

Grading by weight and batching tominimum weight.

A Marel whole bird grader is automated poultry processing equipment designed for the accurate weighing, grading, and batching of whole birds, which reduces labor, increases accuracy, and improves hygiene by minimizing human contact. These systems often feature hygienic, easy-to-clean designs, stainless steel components, and advanced software.

Key Features & Benefits

- Automation & Efficiency: Automates the grading process, significantly reducing the need for manual labor, which saves costs and increases throughput.

- Accuracy & Yield: Precise weighing and grading lead to less "giveaway" (product waste) and better utilization of raw materials, directly increasing profitability.

- Hygiene & Food Safety: Graders are designed with open structures and smooth surfaces for easy cleaning and disinfection, meeting stringent food industry standards.

- Customization: Flexible systems like the ProLine Grader can be configured with standardized components to meet specific production needs and capacities.

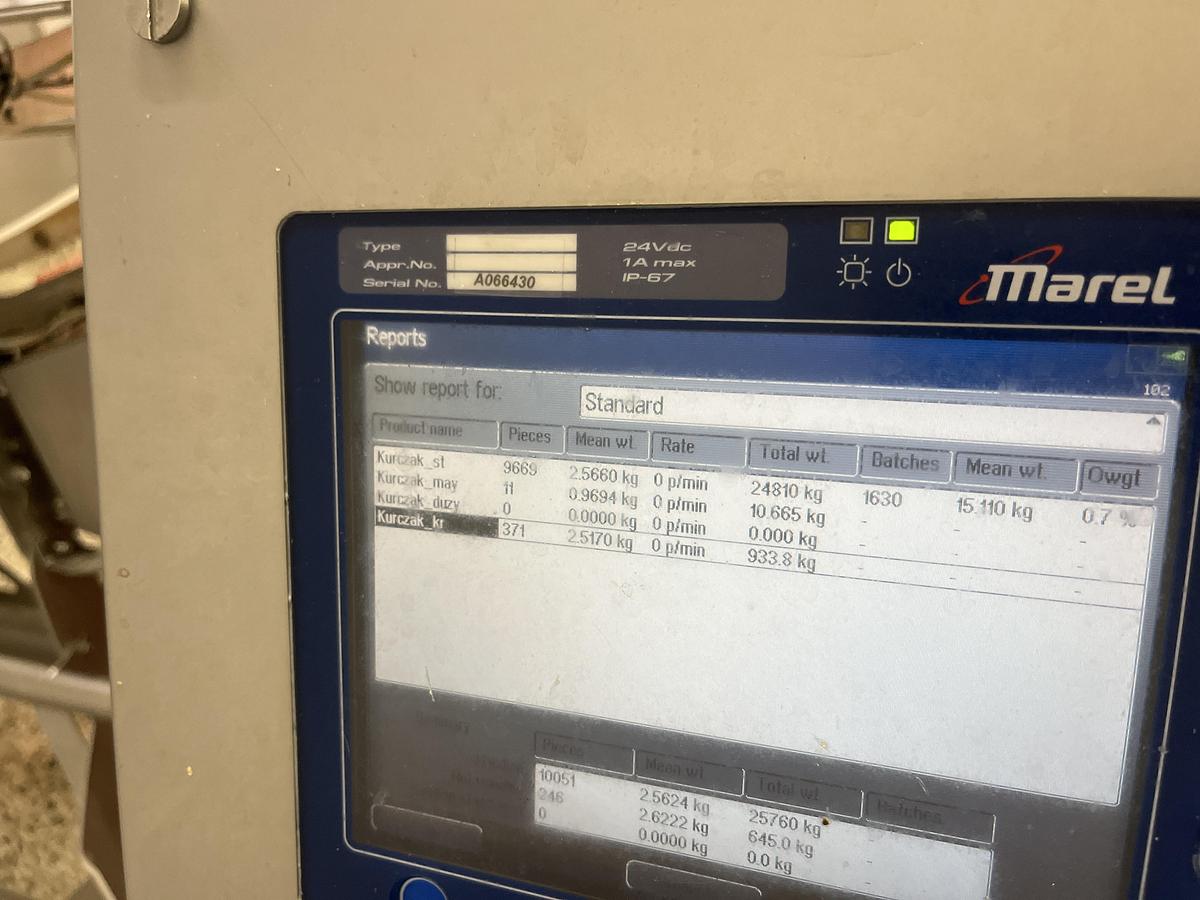

- Data & Traceability: Integrated software, collects production data, allowing for detailed reporting, process optimization, and complete product traceability.

- Versatile Infeed: Various infeed systems are available to accommodate different speeds, bird sizes, and states (e.g., post-chilling).

- Reduced Error: Automation minimizes human error, leading to higher consistency in grading and product quality.

How It Works

- Infeed: Whole birds enter the grader via a suitable infeed system.

- Weighing: Each bird is precisely weighed as it moves along the grader.

- Grading: The system sorts birds into designated grades based on their weight and other criteria.

- Batching: Birds are gently guided into specific chutes or bins for their respective grades.

- Data Collection: Production data is collected and stored for monitoring and analysis.